ROEMHELD UK

High quality and high

accuracy workholding

and handling technology

As a leading manufacturer of workholding products, Roemheld is committed to researching and designing technological innovations that are driven by customer need.

We deliver high quality and high accuracy workholding and handling technology solutions to companies throughout the UK. We also supply hydraulic workholding solutions to a number of the UK’s leading fixture builders.

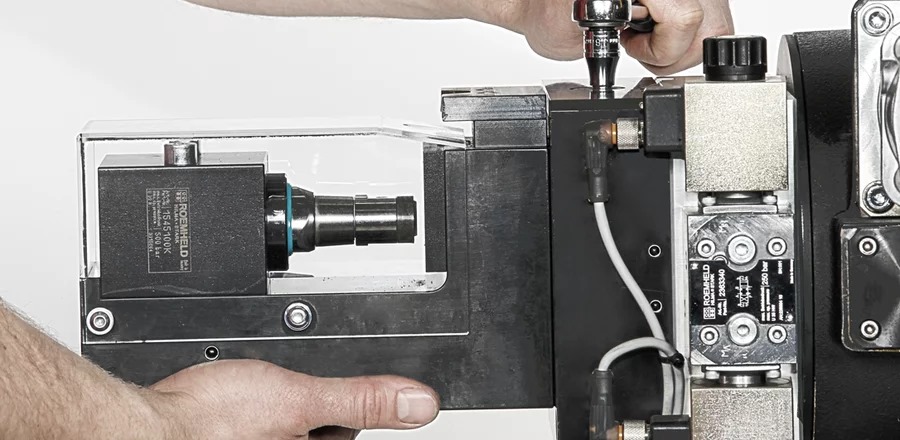

Our diverse product range covers all aspects of workholding and includes high and low pressure hydraulic clamps, work supports and accessories; zero point technology; vice systems including 5-axis clamping; magnetic clamping for use in quick die change and quick mould change; assembly equipment; and lifting and modular handling technology for use in automated cells. We also provide a range of hydraulic and mechanical clamping elements along with tool handling equipment for new and existing presses.

We are able to offer solutions for differing applications across a wide range of industries including automotive, aerospace, medical, machine tools, special purpose machines, plastics and rubber, food and packaging.

STAY UP TO DATE

What we are doing

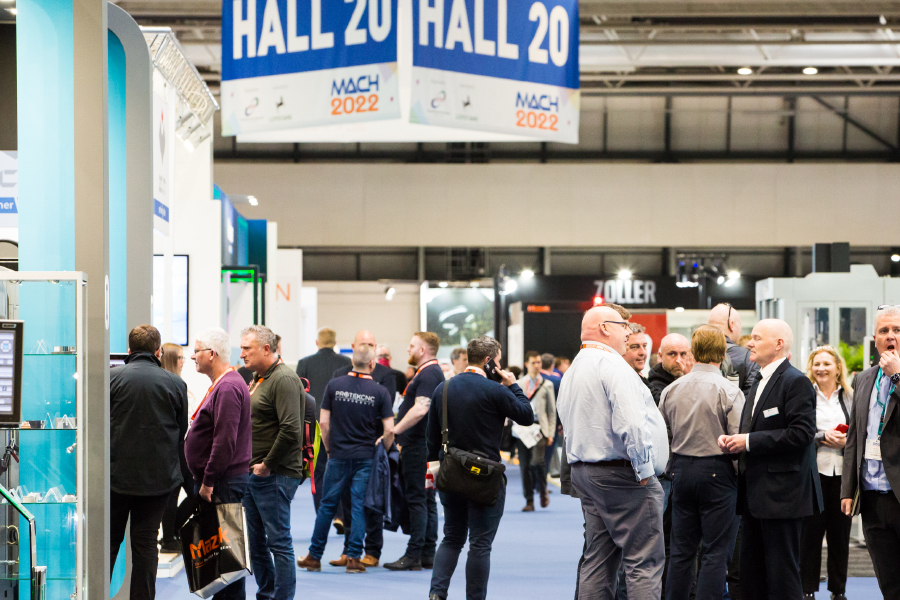

EVENT

MACH 2024

MACH is a fantastic event for both exhibitors and visitors. Showcasing live, digital production systems in one space, under one roof, hundreds

of millions of pounds worth of business is discussed, secured and completed at the event.

CASE STUDY

130 “Bike Promobil” facilitate work on every bike and in every position

How do you assemble 120 different bicycle and e-bike models weighing between 5 and 28 kg quickly and ergonomically? At ROSE Bikes in Bocholt the production is organised as a flow production with flexible assembly carts from ROEMHELD. They are the result of a joint development project. The variable assembly lines are highly productive and ergonomic; with a pleasant and stress-free working atmosphere, the bicycle manufacturer also attracts new employees.

CASE STUDY

Constructive cooperation

If a manufacturer of workholding technology buys several 5-axes machining centres, these should certainly be equipped with their clamping elements and should be a reference for technically feasible solutions concerning effective set-up. The acquisition of three new Grob-Universal machines Series G350 and G550 by the Römheld GmbH required several changes – an effort that was worthwhile for both companies.